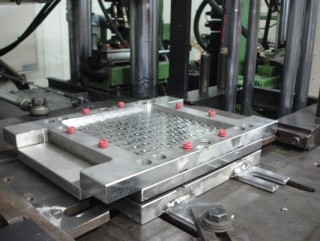

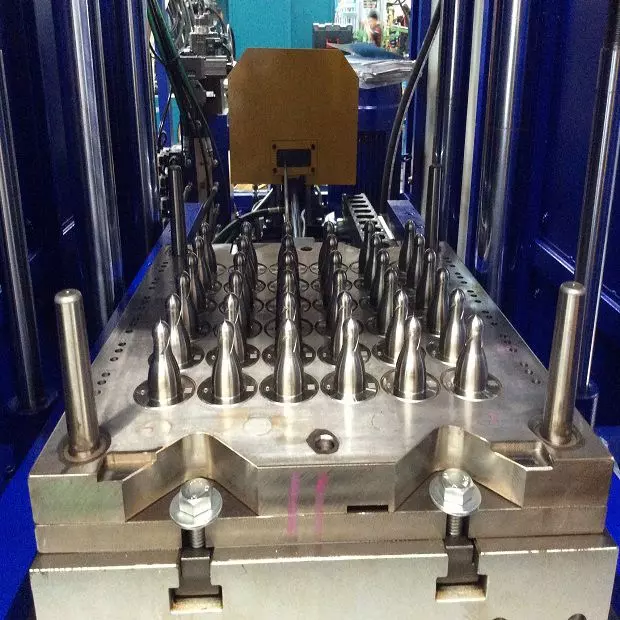

Transfer Injection Mold

Transfer injection molding process is arranging rubber strip on a chamfer mold plate, then leads the rubber flow into injection channel to fill up cavity averagely through compression molding process. The most common rubber part which uses this kind of mold design is valve stem seal or bonded seal. But anyway, L&J will give the best suggestion according to the structure of rubber part which you want to produce.

To do mold test, we usually require the compound rubber from customer in order to 100% simulate the working conditions at customer's side. The more details we notice with good communication, the higher possibility that we can successfully make a very good quality mold. Besides, doing mold test, we not only provide samples for your evaluation, we will also provide the related production parameters of mass production as your reference which should be able to save your time of study to the best working conditions of operating your molds.

For more information in detail, please make contact with us.

- Download

Tags

How Can Transfer Injection Molding Improve Your Valve Stem Seal Production Quality?

Our transfer injection molds ensure uniform rubber distribution and consistent compression, critical for valve stem seal integrity. L&J's comprehensive testing protocol simulates your exact production environment, providing not just prototype samples but complete production parameters that eliminate costly trial-and-error during implementation. Request our detailed rubber mold testing procedure document to see how we can enhance your manufacturing efficiency.

With 17 years of industry experience, our engineering team conducts comprehensive mold testing using customer-supplied compound rubber to perfectly simulate actual production conditions. This meticulous approach ensures seamless integration with your manufacturing processes. Beyond providing sample parts for evaluation, L&J delivers detailed production parameters that significantly reduce your setup time and accelerate time-to-market. Our vertical integration capabilities allow us to offer complete rubber manufacturing solutions from compound formulation through finished products, making us your ideal partner for all rubber molding requirements.