Rubber Mold - Plate

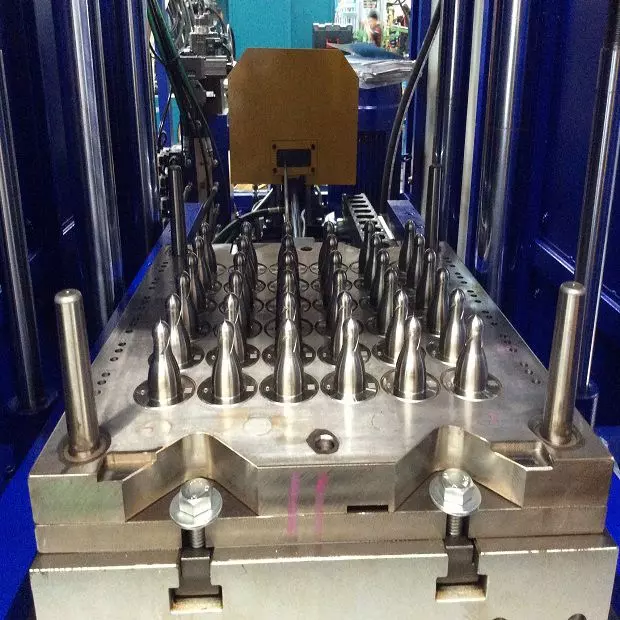

Plate mold is machining cavity directly on mold steel plate or making cavity separately then "insert" it into mold steel plate so the cavity becomes replaceable.

Comparing with cavity mold, the main advantage of using plate mold is to reduce the unit cost of mass production. However, how to control molding pressure with other production parameters well is a technical topic to be dealt with.

On the other hand, you must consider how plate mold coordinates with your machine in working action, heating plate size, pressure output, daylight, stroke, mold fixture, and so on. Those conditions should be coordinated through well communication.

Anyway, rubber plate mold is usually used for making standard & customized rubber component parts. Basically speaking, it has 3 kinds of method which are: Compression, Transfer injection, and Injection molding process.

The selection of what mold type is a professional topic and the first question you have to consider. L&J usually analyses the limitation of mold design, and advantage & weakness of mold type selection from product quality, rubber machine, operating way, and production cost point of view to customer's reference. Customers may also need further suggestions on mold material, mold design, compound rubber, chromate plating, or any other kinds of technical question so L&J would be a very good consultant on those demands.

Doing mold test is also a critical process in mold development. Sometimes a mold maker is not really familiar with mass production conditions and requirements so needs the opinions from professional manufacturing factory to improve mold performance. The risk is, during the mold-test process, the mold supplier cannot distinguish what problem is from mold, what problem is from molding conditions (parameter) in production. L&J has strong resources to integrate the know-how of mass production and mold-making together which makes mold test become more professional to solve problem. Usually this feature is not able to be done from other mold suppliers.

Buying mold from L&J, you don't need to worry about the risk of what if fail unless you cannot clearly explain the materials required for making this mold. We will estimate risk during quotation stage in advance. When we accept your purchase order, it means that we will be responsible to finish this order completely. Even after you approve and receive our molds, we will be pretty serious to do after-sales service well through providing consulting and any possible supports which we are able to do, because selling molds is not just selling, it is also a duty to make sure mold running well.

For more information in detail, please make contact with us.

This is the wooden packing to rubber plate mold with good antirust treatment which is safe for shipment:

High-Precision Compression Molding

Compression molding process is directly arranging rubber strip above cavity then close mold...

DetailsTransfer Injection Mold

Transfer injection molding process is arranging rubber strip on a chamfer mold plate, then...

DetailsHigh-Precision Custom Rubber Injection Molds

L&J International has been specializing in high-precision rubber injection molds since 2006....

DetailsHow Can We Reduce Unit Costs While Maintaining Quality in High-Volume Rubber Component Production?

Our rubber plate mold solutions are specifically designed for mass production cost reduction without compromising quality. We analyze your production parameters, machine compatibility, and molding pressure control to optimize both mold design and manufacturing efficiency. With our integrated mold-making and mass production expertise, we ensure your automotive rubber components meet strict quality standards while achieving significant cost savings. Contact us for a comprehensive analysis of your production requirements and customized mold solutions.

Our integrated approach combines mold-making expertise with mass production know-how, ensuring professional mold testing that distinguishes between mold issues and molding parameter problems. We take full responsibility from quotation through delivery and beyond, offering extensive after-sales consulting and technical support. Our services include guidance on mold material selection, design optimization, compound rubber specifications, chromate plating, and machine coordination factors such as heating plate size, pressure output, daylight, stroke, and mold fixtures. Every mold is delivered with proper antirust treatment and secure wooden packaging for safe international shipment, backed by our commitment to ensuring your molds run successfully in production.