Metal Case

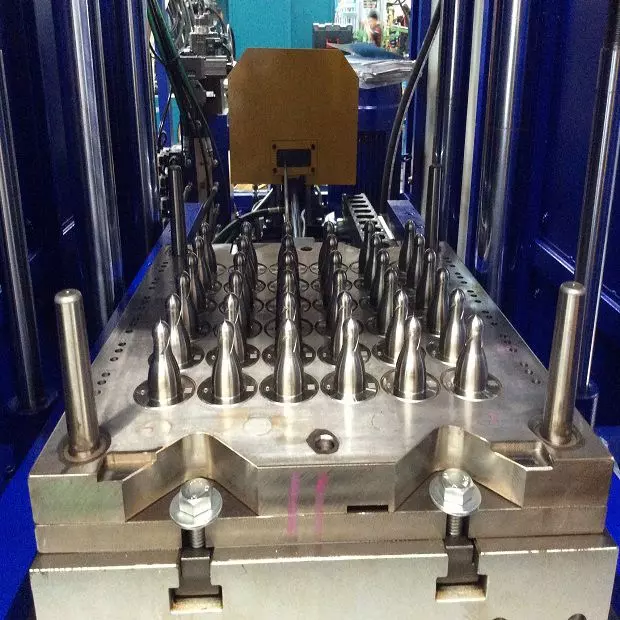

L&J always works with good and professional source in Taiwan. For metal case, the critical key point of quality is the design and accuracy of press mold as well as good production concept in quality control.

The accuracy of metal case is very important to coordinate with compression cavity mold (oil seal). Enquiring L&J, please provide the drawing of metal case design with specification in detail.

How Can You Ensure Metal Case Accuracy Matches Your Oil Seal Compression Molds?

L&J works exclusively with professional Taiwan sources specializing in precision press mold design for metal cases. Our quality control system focuses on dimensional accuracy critical for compression cavity mold coordination. Provide us with your detailed metal case drawings and specifications, and we'll deliver components that integrate seamlessly with your oil seal production process, eliminating fit issues and production delays.

The accuracy of metal cases is paramount for proper coordination with compression cavity molds used in oil seal manufacturing. Understanding this critical requirement, L&J emphasizes meticulous attention to dimensional precision and material specifications. When you enquire with L&J for metal case solutions, we request detailed drawings of your metal case design with complete specifications to ensure we deliver components that perfectly match your production requirements. Trust our established know-how and professional services to provide metal case elements that enhance your oil seal manufacturing efficiency.