Rubber Mold - Cavity

This is one of the main business to L&J all over the world. A good mold plays a very critical role in product quality of manufacturing process. However, every experienced mold buyer knows that buying mold is usually high risky in facing wrong and rough communication or unknown weakness of mold maker's ability.

L&J knows the critical points and has 5 kinds of professional ability which are essential conditions for a good mold supplier to make excellent rubber molds:

(1) Drawing-making of design ability

(2) Manufacturing ability

(3) Mold-testing ability

(4) Dimension-measuring ability

(5) Thoughtful and well-communicating ability.

For a good set of rubber mold, it should has the following 5 features:

(1) Accuracy of dimensions

(2) High good rate

(3) Saving compound rubber, saving electricity

(4) Long mold life time

(5) Good efficiency of mold action (depends on design)

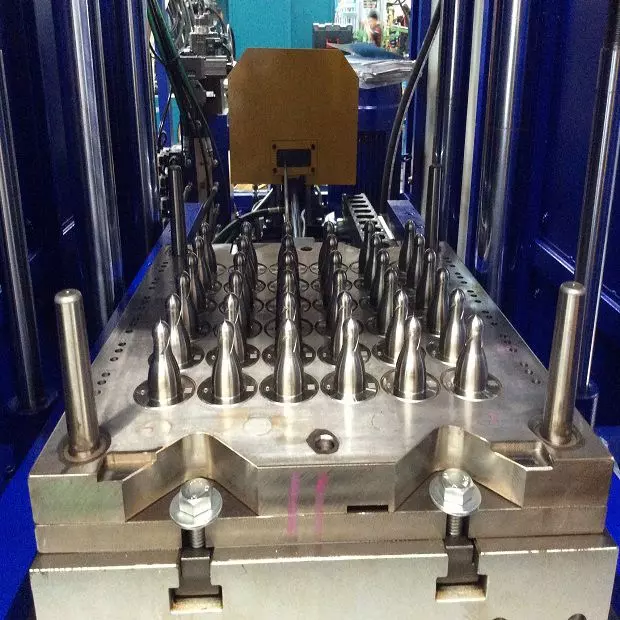

Compression Cavity Mold

Basically compression cavity mold is used for production of oil seal or some kinds of circular...

DetailsHow Can You Reduce Defect Rates and Ensure Dimensional Consistency in High-Volume Rubber Part Production?

Our rubber cavity molds deliver precision dimension accuracy and high good rates through rigorous testing procedures and advanced measuring capabilities. With our structured mold-developing process, automotive manufacturers achieve consistent part quality, minimize scrap rates, and maintain tight tolerances critical for safety components. Contact us to learn how our five-point professional ability system can optimize your production efficiency and reduce costly rework.

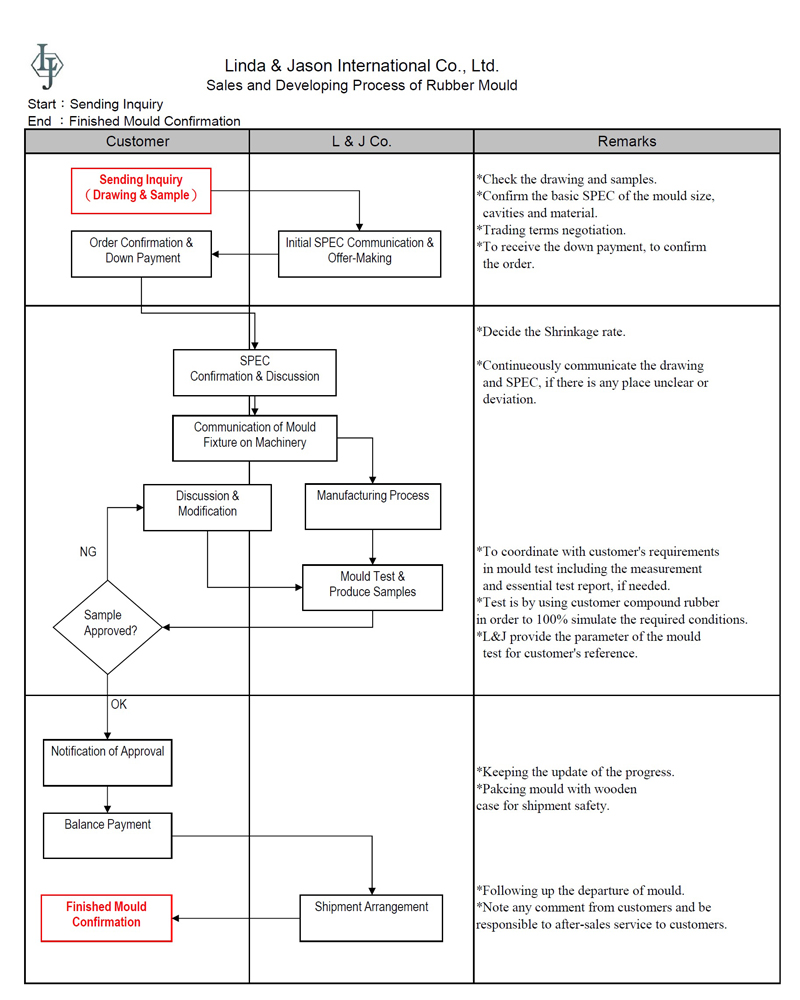

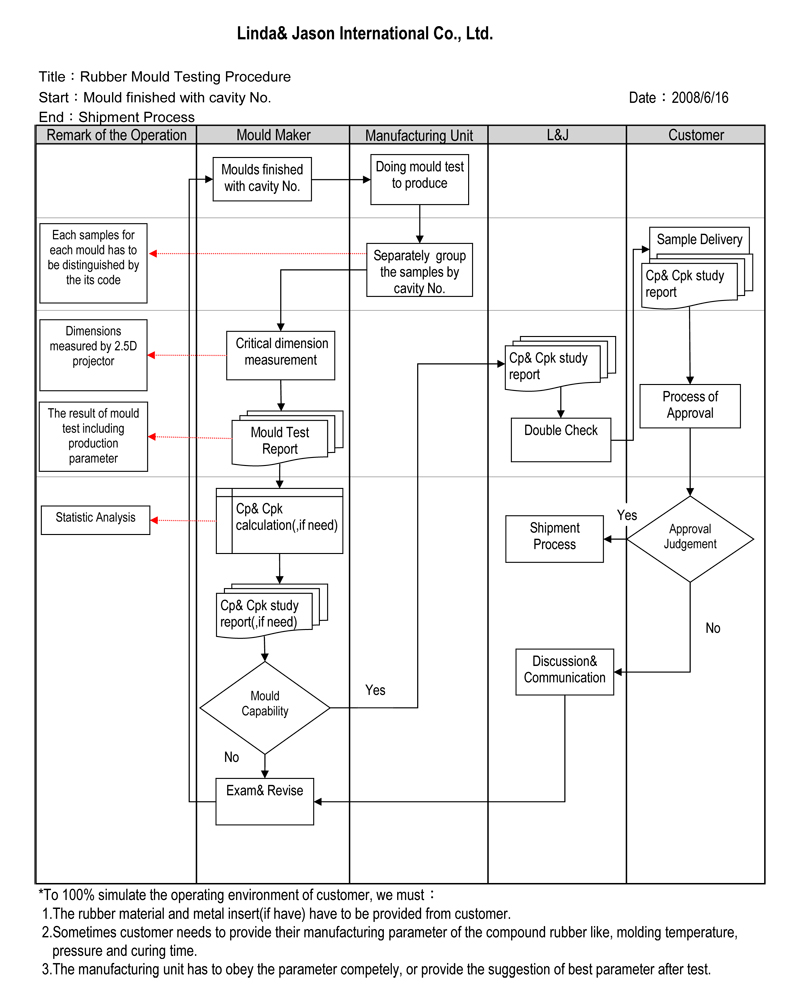

L&J delivers rubber cavity molds featuring five critical characteristics that define excellence: accuracy of dimensions for consistent part production, high good rates that minimize waste, compound rubber and electricity savings for cost efficiency, extended mold life time that maximizes ROI, and superior mold action efficiency through optimized design. Our serious mold-developing process includes structured sales and developing procedures alongside comprehensive rubber mold testing protocols. Through strategic factory cooperation and vertical integration, we share resources and know-how to provide creative, professional solutions backed by expertise in high-end applications across different rubber materials, ensuring quality remains our top priority in every mold we manufacture.