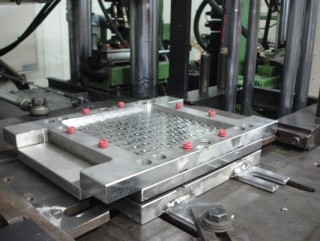

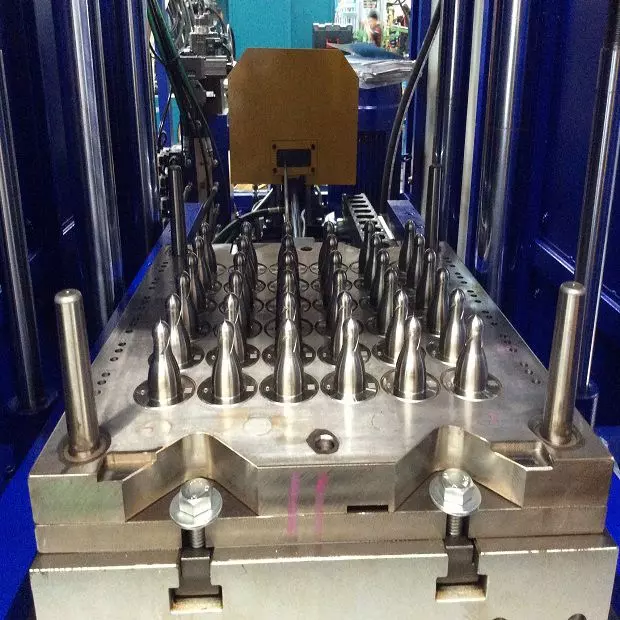

Transfer Injection Mold

Transfer injection molding process is arranging rubber strip on a chamfer mold plate, then leads the rubber flow into injection channel to fill up cavity averagely through compression molding process. The most common rubber part which uses this kind of mold design is valve stem seal or bonded seal. But anyway, L&J will give the best suggestion according to the structure of rubber part which you want to produce.

To do mold test, we usually require the compound rubber from customer in order to 100% simulate the working conditions at customer's side. The more details we notice with good communication, the higher possibility that we can successfully make a very good quality mold. Besides, doing mold test, we not only provide samples for your evaluation, we will also provide the related production parameters of mass production as your reference which should be able to save your time of study to the best working conditions of operating your molds.

For more information in detail, please make contact with us.

- Download

Tags

How Can Transfer Injection Molds Improve Valve Stem Seal Production Consistency?

Our transfer injection molds use precision injection channels to distribute rubber evenly across all cavities, ensuring consistent valve stem seal quality in high-volume automotive production. We provide complete production parameters from mold testing to eliminate trial-and-error, saving you weeks of setup time. Contact us with your compound rubber specifications for a customized mold solution that guarantees repeatability.

To ensure 100% simulation of your working conditions, L&J conducts comprehensive mold testing using customer-supplied compound rubber. Through detailed communication and attention to production parameters, we successfully manufacture high-quality molds that meet exact specifications. Beyond providing evaluation samples, we deliver complete production parameters for mass production operations, significantly reducing your study time and accelerating the path to optimal mold performance. Contact us today to discuss your transfer injection molding requirements and benefit from our strategic alliance system and vertical integration expertise.