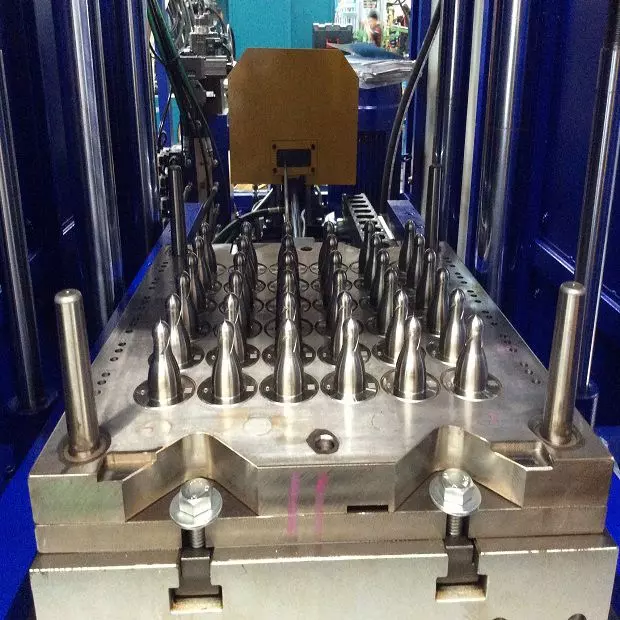

Compression Cavity Mold

Basically compression cavity mold is used for production of oil seal or some kinds of circular rubber part with suitable structure to make.

We have good facility in mold-production, design and measurement.

The capacity of compression cavity mold is 600 cavities per month based on within 10 items.

We are good at mold design and accurate machining with tolerance only ±0.02 ~ ±0.04mm in precision. One general way to prove our precision is that each of our cavity mold part can perfectly match to other mold part by different cavity number, like top layer of cavity No.1 can perfectly match to bottom layer of cavity No.9 without any problem. This is what other mold makers in Taiwan cannot guarantee to achieve.

Enquiring L&J, besides the finished product drawing or sample with made compound rubber, during the discussion to figure out your requirements, we need to know your selections in mold material, engraving SPEC, chromate plating, rubber machine action with mold fixture, mold accessory needs, and so on. Once you are hesitated by those selections, we also can provide our suggestion to design a suitable mold for your needs.

- Compression Cavity Mold - .

- Compression Cavity Mold - .

- Compression Cavity Mold - .

- Compression Cavity Mold - .

- Compression Cavity Mold - .

- Compression Cavity Mold - .

The Maximum Machining Size Of Compression Cavity Mold Is Around 700mm Mold Diameter.

- Compression Cavity Mold - .

- Compression Cavity Mold - .

- Compression Cavity Mold - .

- Compression Cavity Mold - .

- Compression Cavity Mold - .

Wooden packing to compression cavity mold:

Tags

How Can You Achieve Consistent Oil Seal Quality Across High-Volume Production Runs?

L&J's compression cavity molds guarantee ±0.02 to ±0.04mm precision with perfect interchangeability between all cavity parts—ensuring every oil seal meets exact specifications. With 600 cavities per month capacity and proven quality systems, we eliminate production inconsistencies that cost you time and money. Contact us to discuss your oil seal mold requirements and discover how our precision engineering can enhance your manufacturing efficiency.

What sets our compression cavity molds apart is the perfect interchangeability of mold parts—the top layer of cavity No.1 can seamlessly match the bottom layer of cavity No.9 without any issues, a precision guarantee that other Taiwanese mold makers cannot achieve. Our comprehensive service includes mold design consultation, accurate machining, and customization options for mold material selection, engraving specifications, chromate plating, rubber machine action compatibility, and mold accessory requirements. Whether you provide finished product drawings, samples with compound rubber specifications, or need expert guidance in mold design, L&J delivers creative and professional solutions backed by well-established know-how and strategic manufacturing excellence.