Rubber Mold - Cavity

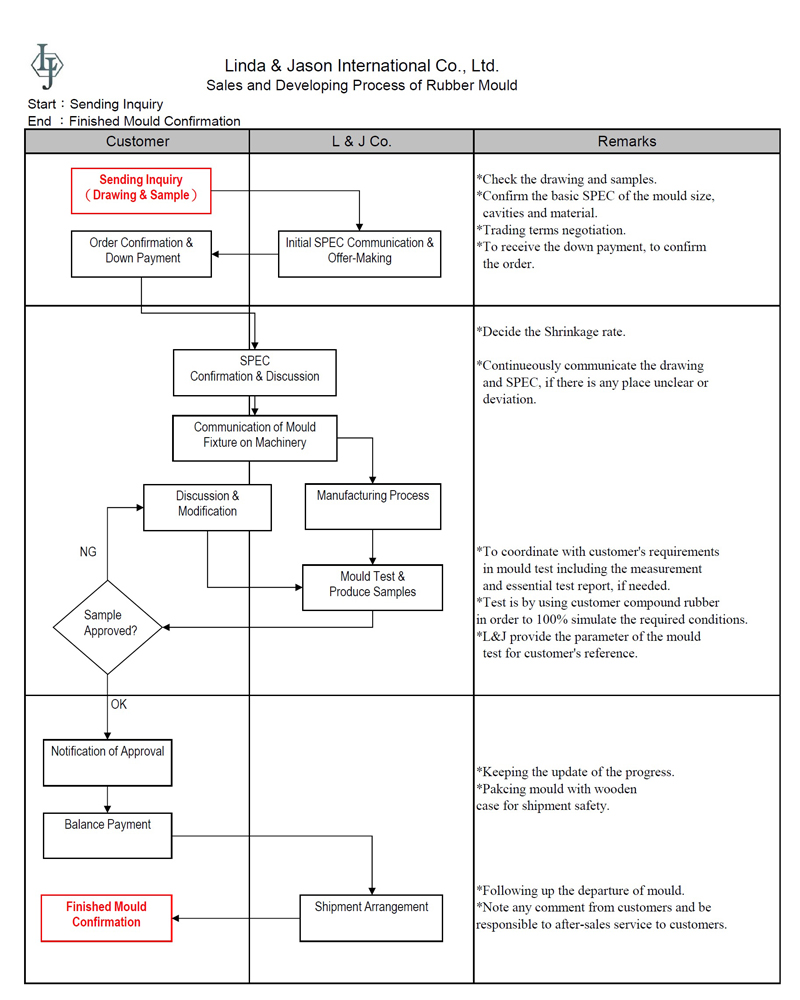

This is one of the main business to L&J all over the world. A good mold plays a very critical role in product quality of manufacturing process. However, every experienced mold buyer knows that buying mold is usually high risky in facing wrong and rough communication or unknown weakness of mold maker's ability.

L&J knows the critical points and has 5 kinds of professional ability which are essential conditions for a good mold supplier to make excellent rubber molds:

(1) Drawing-making of design ability

(2) Manufacturing ability

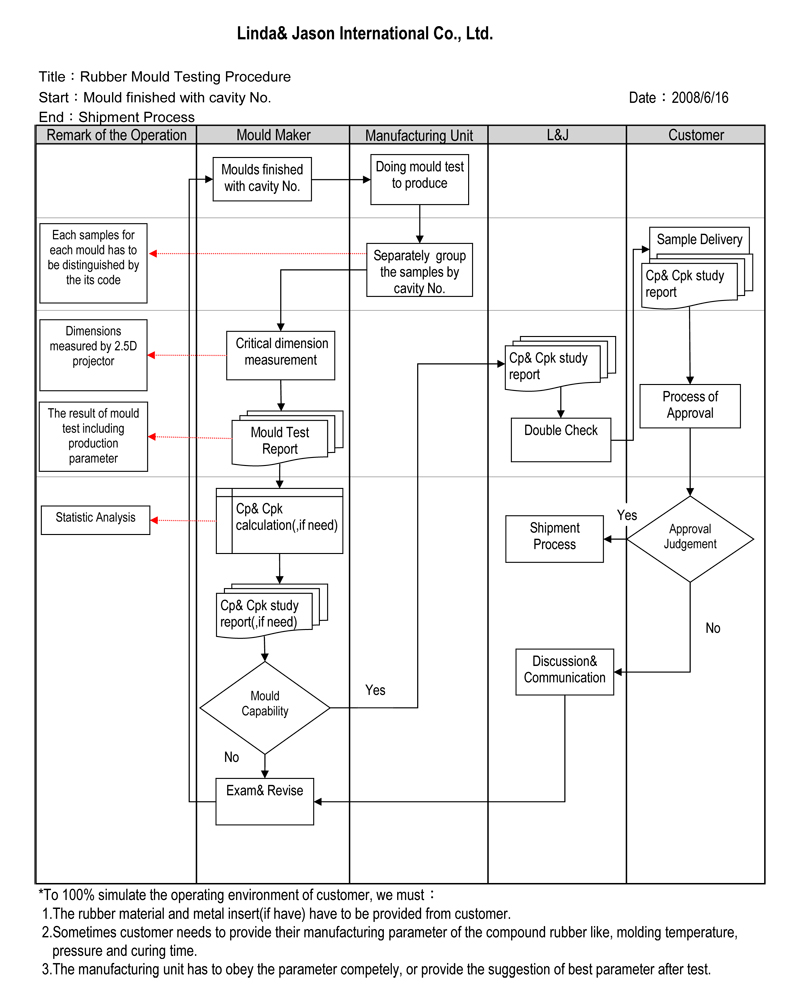

(3) Mold-testing ability

(4) Dimension-measuring ability

(5) Thoughtful and well-communicating ability.

For a good set of rubber mold, it should has the following 5 features:

(1) Accuracy of dimensions

(2) High good rate

(3) Saving compound rubber, saving electricity

(4) Long mold life time

(5) Good efficiency of mold action (depends on design)

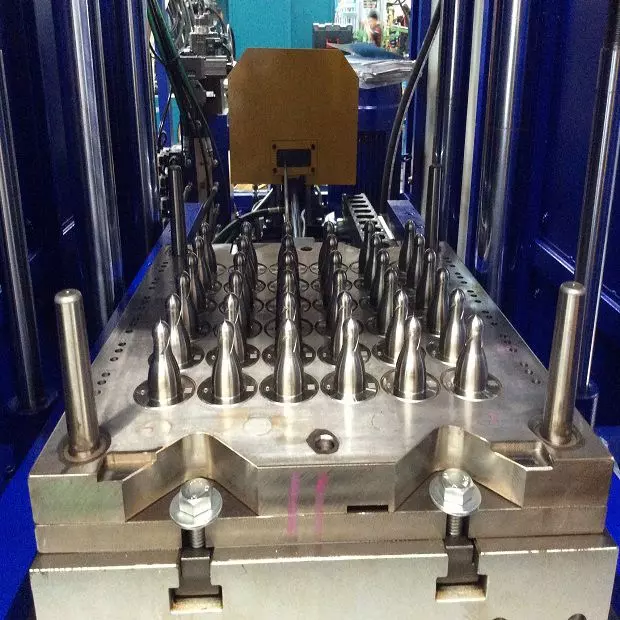

Compression Cavity Mold

Basically compression cavity mold is used for production of oil seal or some kinds of circular...

DetailsWhy are L&J compression cavity molds the preferred choice for oil seal production?

L&J compression cavity molds are specifically engineered for circular components like oil seals, delivering unmatched dimensional accuracy and consistency. Our molds are designed to optimize material usage, reduce energy consumption, and provide exceptional durability through thousands of production cycles. With our rigorous testing procedures and specialized design expertise, we ensure your oil seal production achieves higher yields, better quality, and improved efficiency. Request a consultation to optimize your oil seal manufacturing process.

Each rubber mold we produce embodies our commitment to excellence through five key features: uncompromising dimensional accuracy, consistently high production yields, optimized material and energy efficiency, extended mold lifespan, and superior operational efficiency. Our rigorous development and testing procedures guarantee that every mold meets exacting standards before delivery. As a vertical integration supplier in the rubber industry, L&J provides comprehensive solutions from compound rubber formulation to finished mold production, making us the trusted partner for manufacturers seeking reliability and precision in their rubber molding processes.