Oil Seal

Oil seal is a specific product range in rubber industry which generally is used for automobile, motorcycle, mechanical, or any kind of industry which needs to seal (resist) oil, liquid, air, pressure, temperature, friction, dust, and so on.

Here is no need to explain too much knowledge about oil seal because a professional buyer knew that already or we can explain to learning customers in private. Here we would like to explain what a buyer should know most in transaction and what we can provide to customers.

Buying oil seal, generally customers focus on the following features to a supplier:

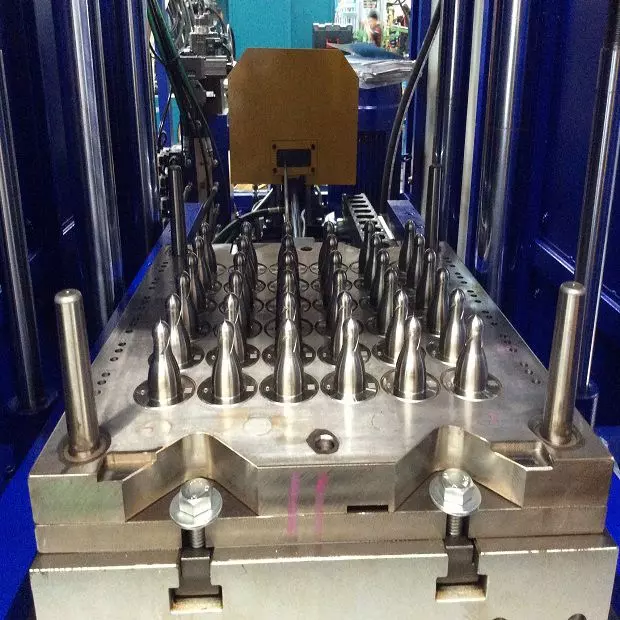

(1) Whether the existing mold items are complete enough to handle all different size and type?

(2) Whether the quality is good & stable including QC control?

(3) Whether the price is competitive comparing with its quality level?

(4) Whether the lead time is fast without delay and packing is safe for delivery?

(5) Whether the after-sales service is well?

(6) Whether the working attitude is well in coordination and communication all the time?

Yes, we are good at above, except 1., the existing mold items are always under expanding.

Generally speaking, L&J is good at oil seal developing project because of the following 4 reasons:

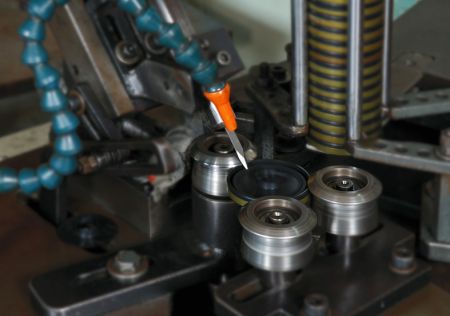

(1) Well complete facility of production line and test equipments.

(2) Knowledgeable about property of compound rubber and always use good quality compound.

(3) Experienced at oil seal mold design.

(4) Strict quality control process.

However, the level of buying oil seal are usually diversified so it causes different working way and cost structure like OEM and after service level which are very different.?L&J tries to handle both demand well because our working system is proactive in growing.? So, please send your enquiry with essential information in detail as possible as you can.

Enquiring L&J, please at least advise us essential information as:

(1) Oil seal size, type, and compound rubber.

(2) If you don't clearly know the specification, sending sample or drawing design to us is Okay as well.

(3) Quantity (important).

(4) Special demand, if you need, like working condition, compound rubber property requirements, and so on.

Present Specification in Stock

L&J has some existing oil seal specification in stock which can afford the small quantity purchase...

DetailsHow Can We Ensure Consistent Oil Seal Quality for High-Volume Automotive Production?

L&J's complete production line facilities, combined with strict quality control processes and deep compound rubber knowledge, guarantee stable quality for your automotive oil seal requirements. Our experienced mold design team and comprehensive test equipment ensure every batch meets OEM standards. Contact us with your specifications, quantity requirements, and working conditions to receive a detailed quality assurance plan tailored to your production needs.

Our proactive working system enables us to handle both OEM-level projects and after-service market demands effectively, with continuously expanding mold inventory to meet diverse customer requirements. Whether you need standard oil seal specifications or custom development projects, L&J's strategic alliance system and vertical integration capabilities ensure creative and professional solutions tailored to your specific working conditions and compound rubber property requirements. We welcome inquiries with detailed specifications including oil seal size, type, compound rubber requirements, quantity, and any special demands—or simply send us samples or design drawings for evaluation and quotation.